The breaking strength of fiberglass fabrics is an important indicator of their material properties and is influenced by factors such as fiber diameter, weave, and post-treatment processes. Standard test methods allow the breaking strength of fiberglass cloths to be evaluated and the materials suitable for specific applications to be selected accordingly.

In the field of materials science, fiberglass cloth, as a common reinforcing material for composites, is directly related to the quality and performance of the final product. The breaking strength of fiberglass cloth, as one of the important indexes to measure its material properties, is of great concern. So, how is the breaking strength of fiberglass cloth defined? What factors affect it? And how to test it?

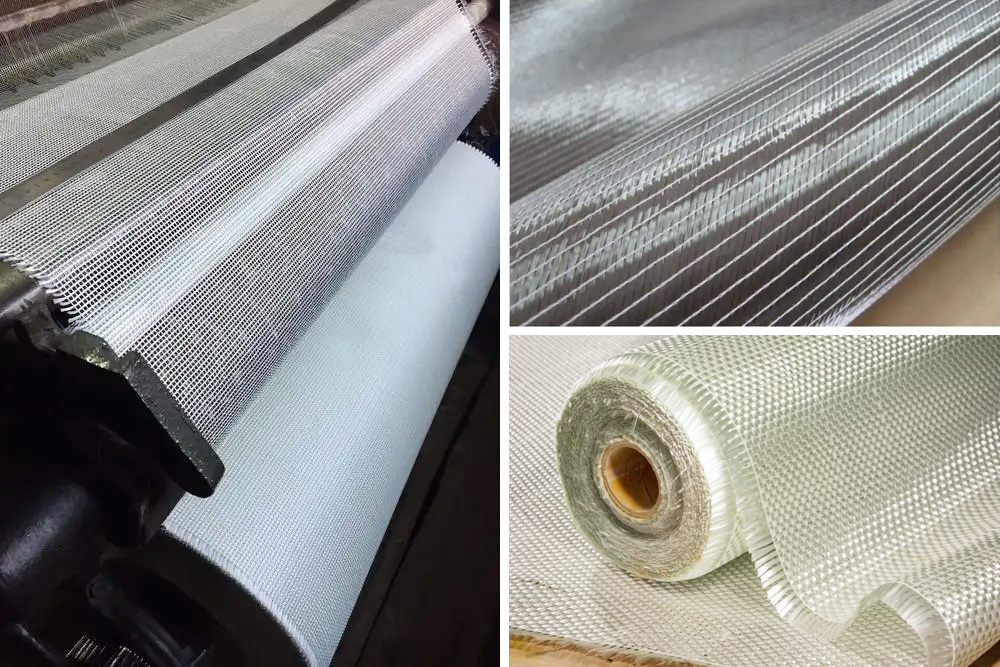

Structure and properties of fiberglass cloth

Fiberglass cloth is mainly made of fiberglass after weaving, its structure determines its unique performance. Fiberglass has the advantages of high strength, high modulus, corrosion resistance, abrasion resistance, etc., while the woven glass fiber cloth has good processability and tensile resistance. However, in the actual use of the process, the glass fiber cloth may also be due to external forces and breakage. At this time, the breaking strength has become a key indicator of its performance.

Factors affecting the breaking strength of fiberglass cloth

1. Fiber diameter: the smaller the fiber diameter, the greater the number of fibers per unit area, which improves the strength and toughness of the fiberglass cloth. However, too small a fiber diameter will also increase the friction and wear between the fibers, reducing its service life.

2. Weaving method: Different weaving methods will affect the structure and performance of the fiberglass cloth. For example, plain weave fiberglass fabric has better tensile strength and stability, while twill weave fiberglass fabric has better elasticity and abrasion resistance.

3. Post-treatment processes: Post-treatment processes such as heat treatment, coating, etc. also have an effect on the breaking strength of fiberglass fabrics. Proper post-treatment process can improve the strength and durability of fiberglass fabric.

Test Methods for Fiberglass Cloth Breaking Strength

In order to accurately assess the breaking strength of fiberglass fabrics, standard test methods are usually used. These methods include tensile test, tear test, impact test, and so on. Through these tests, the breaking strength of fiberglass cloth can be measured under different conditions, and its performance can be evaluated accordingly.

Importance of Fracture Strength in Fiberglass Cloth Applications

In practical applications, the breaking strength of glass fiber cloth is directly related to the quality and performance of products. For example, in the aerospace field, the strength of the material is very high, and only fiberglass cloth with high breaking strength can meet this requirement. In the construction industry, fiberglass fabrics are often used to enhance the performance of concrete and other materials, and their breaking strength is also one of the most important indicators for evaluating their performance. Therefore, when selecting fiberglass fabrics, performance parameters such as breaking strength need to be fully considered to ensure the quality and performance of the final product.

Post time: Feb-05-2025