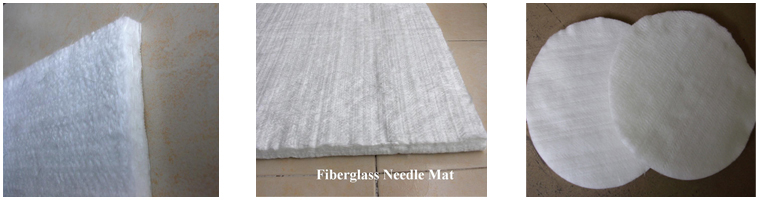

1. Needle felt

Needle felt is divided into chopped fiber needle felt and continuous strand needle felt. Chopped fiber needled felt is to chop the glass fiber roving into 50mm, randomly lay it on the substrate placed on the conveyor belt in advance, and then use a barbed needle for needle punching, and the needle will pierce the chopped fiber into the substrate And the crochet hook brings up some fibers to form a three-dimensional structure. The substrate used can be a thin fabric of glass fiber or other fibers, and this needled felt has a fluffy feel. Its main uses include heat insulation and sound insulation materials, heat lining materials, filter materials, and can also be used in the production of FRP, but the strength of the FRP is low and the scope of use is limited. Another type of continuous strand needle felt is a felt in which continuous glass strands are randomly thrown onto a continuous mesh belt with a wire throwing device, and then needled through a needle plate to form a three-dimensional structure in which fibers are intertwined. This kind of felt is mainly used in the production of glass fiber reinforced thermoplastic stampable sheets.

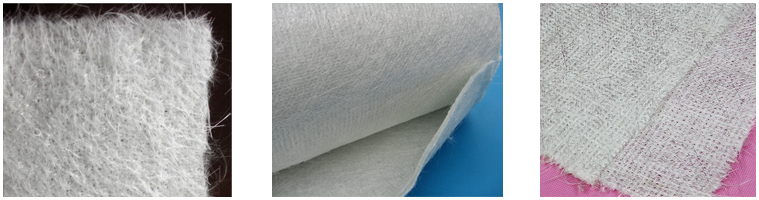

2. Fiberglass Chopped Strand Mat - Powder binder

The glass raw filaments formed during the drawing process or the continuous raw filaments retired from the raw filament tube are laid on a continuous moving mesh belt in a figure of 8 and are bonded by a powder adhesive. The fiber in the continuous glass fiber mat is continuous, so it has a better reinforcement effect on the composite material.

3. Fiberglass Chopped strand mat – Emulsion binder

Cut the glass fiber (sometimes also use untwisted roving) into 50mm length, spread it randomly but evenly on the mesh belt, and then apply emulsion adhesive or sprinkle powder binding agent to heat and solidify and bond it into short Cut raw silk felt. Chopped strand mats are mainly used in hand lay-up, continuous board making and compression molding and SMC processes. The quality requirements for chopped strand mats are as follows: ①The area quality is uniform along the width direction; ②The chopped strands are evenly distributed in the mat surface without large holes, and the binder is evenly distributed; ③Has moderate dry mat strength; ④Excellent The resin infiltration and permeability.

Post time: Aug-12-2021