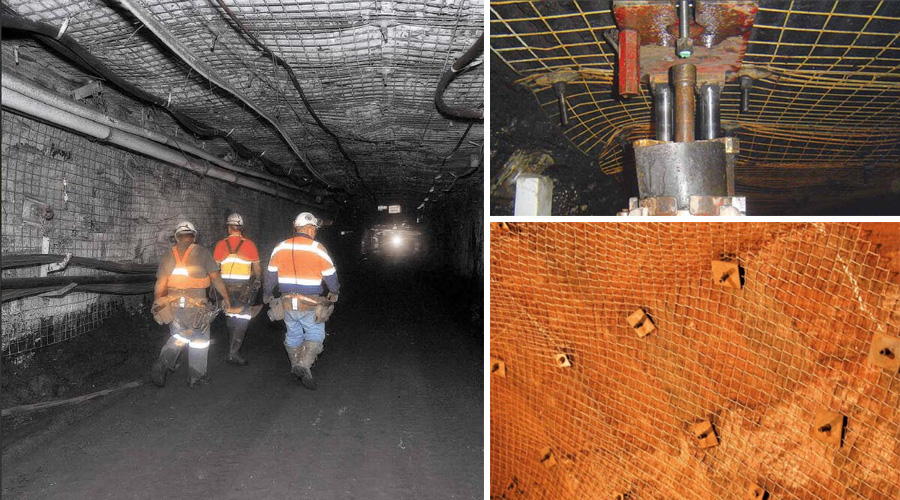

In the fast-paced world of mining, safety and efficiency are paramount. With the introduction of fiberglass rockbolts, the mining industry is experiencing a revolutionary shift in the way it approaches underground operations. These innovative rockbolts, made from glass fiber, are proving to be a game-changer for mining companies around the world.

Traditionally, steel rockbolts have been the go-to choice for securing rock formations in underground mines. However, the introduction of fiberglass rockbolts has opened up a new realm of possibilities for the industry. These rockbolts are not only lighter and easier to handle than their steel counterparts, but they also offer superior corrosion resistance and durability, making them an ideal choice for the harsh underground mining environment.

One of the key advantages of fiberglass rockbolts is their non-conductive nature, which eliminates the risk of electrical conductivity in underground mines. This is particularly important in mines where mining machines and equipment are in operation, as it reduces the risk of electrical accidents and enhances overall safety for miners and workers.

In addition to their safety benefits, fiberglass rockbolts also contribute to increased efficiency in mining operations. Their lightweight nature makes them easier to transport and install, reducing the time and labor required for rock reinforcement. This, in turn, leads to cost savings for mining companies and allows for more streamlined operations.

The use of fiberglass rockbolts is also contributing to environmental sustainability in the mining industry. As a non-metallic material, fiberglass is not subject to corrosion, reducing the need for frequent replacements and minimizing the environmental impact of mining activities. This aligns with the industry’s growing focus on sustainable practices and responsible resource extraction.

The adoption of fiberglass rockbolts is gaining momentum in the mining industry, with companies recognizing the numerous benefits they offer. From increased safety to enhanced efficiency and environmental sustainability, these innovative rockbolts are reshaping the way underground mining operations are conducted.

As the demand for fiberglass rockbolts continues to grow, manufacturers are investing in research and development to further improve their performance and durability. This ongoing innovation is driving the evolution of rock reinforcement technology and paving the way for a safer, more efficient, and sustainable future for the mining industry.

In conclusion, the introduction of fiberglass rockbolts represents a significant advancement in underground mining practices. By prioritizing safety, efficiency, and environmental responsibility, these innovative rockbolts are shaping the future of mining and setting new standards for rock reinforcement in underground operations. As the industry continues to embrace this technology, the potential for further advancements and improvements is limitless, promising a brighter and safer future for mining professionals around the world.

Post time: Apr-24-2024