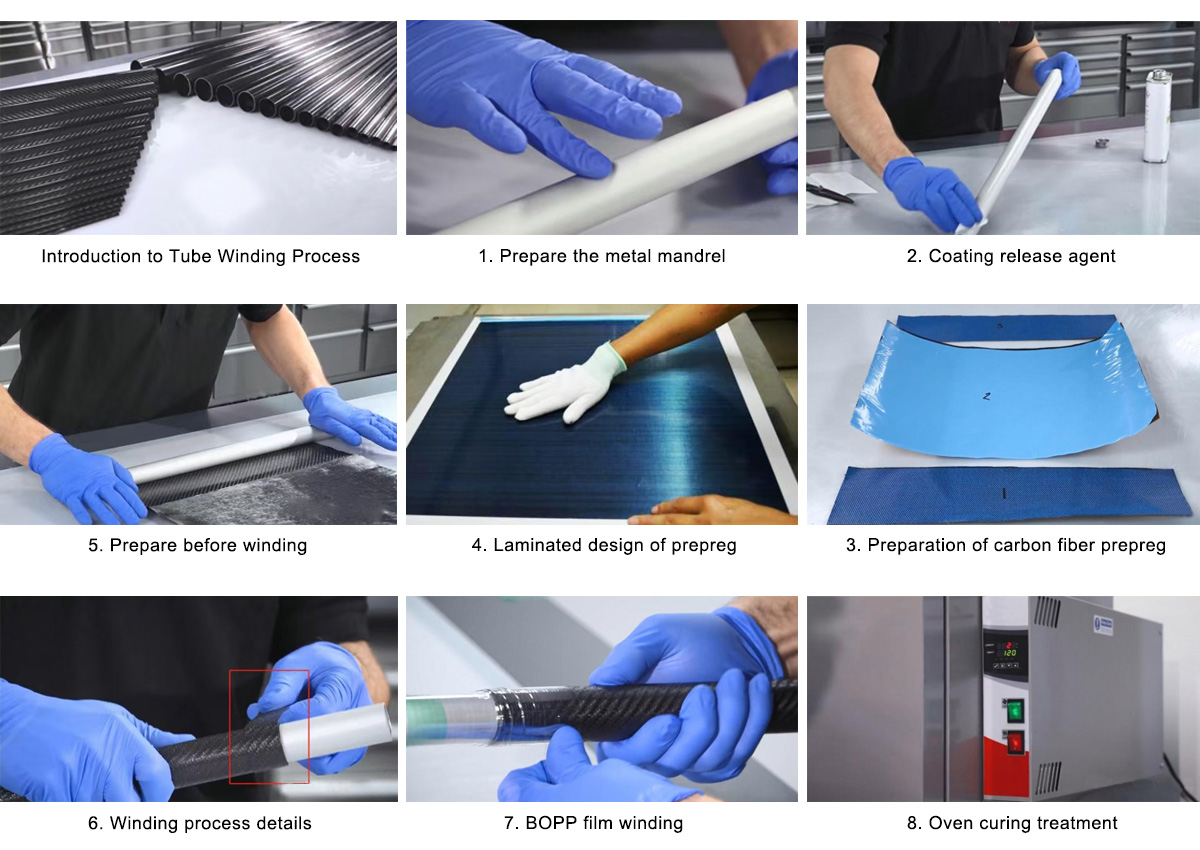

1. Introduction to Tube Winding Process

Through this tutorial, you will learn how to use the tube winding process to form tubular structures using carbon fiber prepregs on a tube winding machine, thereby producing high-strength carbon fiber tubes. This process is commonly used by composite material manufacturers.

If you wish to produce tubes with parallel sides or continuous taper, the tube winding process is the ideal choice. All you need is a metal mandrel of the appropriate size and an oven to create custom carbon fiber tubes tailored to your specific requirements.

For complex-shaped carbon fiber tubes, such as handlebars or more intricate tubular frame structures like suspension forks or bicycle frames, split-mold technology is the preferred method. We will now demonstrate how to use split-mold technology to produce these complex carbon fiber tubes.

2. Processing and Preparation of Metal Mandrels

- The Importance of Metal Mandrels

Before beginning the tube winding process, the first step is to prepare the metal mandrels. The metal mandrels must match the inner diameter of the tubes, and their surface smoothness and appropriate pre-treatment are critical. Additionally, the metal mandrels must undergo proper pre-treatment, such as cleaning and applying a release agent, to simplify the subsequent demolding process.

During the tube winding process, the metal mandrel plays a crucial role as it must support the carbon fiber prepreg to ensure smooth winding. Therefore, preparing the appropriate size of metal mandrel in advance is essential. Since the carbon fiber will be wound around the outer surface of the mandrel, the outer diameter of the mandrel must match the inner diameter of the carbon fiber tube to be manufactured.

- Applying release agent

Release agents reduce friction and ensure smooth demolding; they must be evenly applied to the mandrel surface. After the metal mandrel is prepared, the next step is to apply the release agent. Commonly used release agents include silicone oil and paraffin, which effectively reduce friction between the carbon fiber and the metal mandrel.

On the prepared metal mandrel, we must ensure it is thoroughly clean and the surface as smooth as possible to facilitate smooth demolding of the product. Subsequently, the release agent should be evenly applied to the surface of the mandrel.

3. Preparation of carbon fiber prepreg

- Types and advantages of prepreg

Only carbon fiber prepregs meet the high requirements for winding accuracy and ease of handling. Although other types of reinforcing materials, such as epoxy-impregnated dry fabrics, could theoretically be used in the winding process, in practice, only carbon fiber prepregs can meet the high requirements for precision and ease of handling in this process.

In this tutorial, we use a specific prepreg layering method to enhance the performance of the tubing.

- Prepreg Layup Design

A layer of woven prepreg is laid on the inner side of the tube, followed by several layers of unidirectional prepreg, and finally another layer of woven prepreg is applied on the outer side of the tube. This layup design fully leverages the fiber orientation advantages of woven prepreg at the 0° and 90° axes, significantly enhancing the tube’s performance. The majority of unidirectional prepregs laid on the 0° axis confer excellent longitudinal stiffness to the pipe.

4. Pipe winding process flow

- Pre-winding preparation

After completing the prepreg layup design, the process proceeds to the pipe winding process. Prepreg processing involves removing the PE film and release paper, and reserving appropriate overlap areas. This step is critical for ensuring the smooth progression of subsequent winding processes.

- Details of the winding process

During the winding process, it is essential to ensure smooth winding of the prepregs, with the metal core shaft placed steadily and force applied uniformly. The metal core shaft should be placed steadily at the edge of the first layer of prepregs, ensuring even force application.

During winding, additional prepregs can be wound at the ends to facilitate product removal during demolding.

- BOPP Film Wrapping

In addition to prepreg, BOPP film can also be used for wrapping. BOPP film increases consolidation pressure, protects, and seals the prepreg. When applying BOPP wrapping film, it is crucial to ensure sufficient overlap between the tapes.

5. Oven Curing Process

- Curing Temperature and Time

After tightly wrapping the prepreg carbon fiber reinforced material, it is sent to the oven for curing. Temperature control is critical during curing in the oven, as different prepregs have different curing conditions. This step is crucial for ensuring material stability and enhancing performance.

Through the high-temperature environment in the oven, the carbon fiber and resin matrix react fully, forming a robust composite material.

6. Removal and Processing

After removing the BOPP wrapping film, the cured product can be removed. The BOPP film can be removed after curing. If necessary, the appearance can be improved through sanding and painting. For further aesthetic enhancement, additional finishing processes such as sanding and painting can be performed.

Post time: Aug-11-2025