Fiberglass Yarn Series

Product Introduction

E-glass fiberglass yarn is an excellent inorganic non-metallic material. Its monofilament diameter ranges from a few micrometers to tens of micrometers, and each strand of roving is composed of hundreds or even thousands of monofilaments. The company’s E-glass fiberglass yarn products are of excellent quality, featuring advantages such as high yarn strength and low fuzz; uniform linear density and strong processability; low moisture absorption and good physicochemical properties; excellent electrical insulation and heat resistance.

Application Fields

E-glass fiberglass yarn is mainly used in various sectors of the national economy such as electronic base cloth, grinding wheel reinforced mesh, filter cloth, and reinforced fire-resistant construction cloth, which are industrially woven for purposes including reinforcement, insulation, corrosion resistance, thermal insulation, and dust filtration.

|

Type |

Monofilament Diameter(μm) |

Count (tex) |

Sizing Agent |

|

Direct Roving |

9 |

68 |

Silane Type / Paraffin Type |

|

11 |

68 |

||

|

11 |

100 |

||

|

13 |

134 |

||

|

13 |

200 |

||

|

13 |

270 |

||

|

13 |

300 |

||

|

14 |

230 |

||

|

14 |

250 |

||

|

14 |

330 |

||

|

14 |

350 |

||

|

15 |

400 |

||

|

15 |

550 |

||

|

16 |

600 |

||

|

Twisted Yarn |

9 |

50 |

|

|

11 |

68 |

||

|

11 |

100 |

||

|

11 |

136 |

||

|

Assembled Roving |

9 |

50*2/3/4 S/Z-plied yarn |

|

|

11 |

68*2/3/4 S/Z-plied yarn |

||

|

11 |

100*2/3/4 S/Z-plied yarn |

||

|

11 |

136*2/3/4 S/Z-plied yarn |

Fiberglass Mesh Series

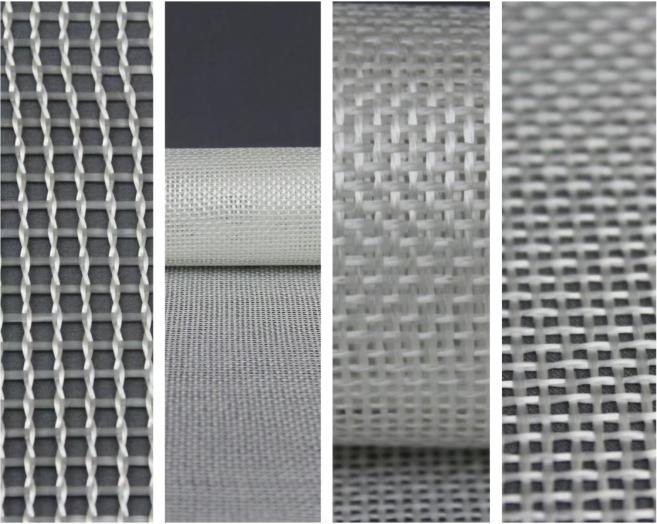

Introduction to Fiberglass Mesh Cloth

Fiberglass mesh cloth uses fiberglass woven fabric as its base material, which is then coated by being immersed in a polymer anti-emulsion. This gives it good alkali resistance, flexibility, and high tensile strength in both warp and weft directions, making it widely used for thermal insulation, waterproofing, and crack resistance on interior and exterior walls of buildings. Fiberglass mesh cloth mainly uses alkali-resistant fiberglass mesh, which is woven using medium-alkali or alkali-free fiberglass yarn (whose main component is silicate, providing good chemical stability) through a special organizational structure—the leno weave—and is then treated with high-temperature heat setting using anti-alkali liquid and strengthening agents. The product features good alkali resistance, chemical stability; stable dimensions and excellent positioning; high strength, good toughness, impact resistance, and light weight; insulation, fire resistance, insect resistance, and mold resistance; strong adhesion to resins, and easy solubility in styrene.

Application Fields

Widely used for the reinforcement and crack resistance of materials such as exterior wall thermal insulation finishing systems, cement products, asphalt, marble, mosaic, partition boards, magnesia boards, fireproof boards, plaster products, roof waterproofing, and GRC components, making it an ideal engineering material for the construction industry.

Product Specifications

|

Model Specification |

Glue Content (%) |

Tensile Strength (N/50mm) |

Weave Gram |

||||

|

Weight (g/m²) |

Mesh Count |

Mesh Size (mm) |

Warp (N) |

Weft (N) |

Positioning (N) |

||

|

70 |

5 |

5*5 |

16% |

>=600 |

>=700 |

>=1.5 |

Leno Weave |

|

100 |

5 |

5*5 |

15% |

>=600 |

>=700 |

>=2.0 |

|

|

110 |

2.5 |

10*10 |

16% |

>=700 |

>=650 |

>=2.0 |

|

|

125 |

5 |

5*5 |

14% |

>=1200 |

>=1250 |

>=2.5 |

|

|

145 |

5 |

5*5 |

14% |

>=1200 |

>=1450 |

>=3.0 |

|

|

160 |

5 |

4*4 |

14% |

>=1400 |

>=1700 |

>=3.5 |

|

|

250 |

5 |

3*3*6 |

14% |

>=2200 |

>=2300 |

>=4.5 |

|

|

300 |

5 |

3*3*6 |

14% |

>=2500 |

>=2900 |

>=6.0 |

|

Introduction to Flame-Retardant Fiberglass Mesh Cloth

Flame-retardant fiberglass mesh cloth is a special type of mesh cloth primarily used in EIFS (Exterior Insulation and Finish System). It is customized for buildings with extra fire-resistance requirements. It is woven from fiberglass mesh and then coated with flame-retardant latex. The coating not only protects the fiberglass from acidic substances but also prevents the spread of fire. Therefore, the EIFS system will not catch fire and can remain intact even after being ignited. Flame-retardant fiberglass mesh is very popular in North American regions such as the United States, Canada, and Mexico, offering advantages such as fire resistance, ultra-softness, and high tensile strength. When embedded in the EIFS system, it acts as a “soft reinforcement,” which prevents the entire insulation system from deforming due to external pressure or extrusion, thereby greatly improving the durability and service life of the insulation system.

Application Fields

Substrate and reinforcing material for various flame-retardant materials.

Product Specifications

|

Model Specification |

Glue Content (%) |

Tensile Strength (N/50mm) |

Weave Gram |

||||

|

Weight (g/m²) |

Mesh Count |

Mesh Size (mm) |

Warp (N) |

Weft (N) |

Positioning (N) |

||

|

160+-3 |

6 |

4*4 |

14% |

>=1400 |

>=1700 |

>=3.5 |

Leno Weave |

Composite Abrasive Series

Fiberglass grinding wheel mesh is a mesh fabric woven from high-strength fiberglass yarn. It serves as the reinforcing substrate for resin-bonded grinding wheels, used for metal cutting and grinding. It features high strength in warp and weft directions, dimensional stability, excellent heat and chemical resistance, high-speed cutting performance, and high structural strength.

Application Fields

Fiberglass grinding wheel mesh is the base material for various abrasive tools. Abrasive tools, represented by the flap disc, are used for rough grinding, semi-finish grinding, and finish grinding, as well as slotting and cutting, of external circles, internal circles, flat surfaces, and various profiles of metal or non-metal workpieces.

Product Specifications

|

Model Specification |

Weave Gram |

Weight(g/m²) |

Width (cm) |

Yarn Used |

Mesh Count |

||

|

Warp |

Warp |

Warp |

Weft |

||||

|

EG5*5-160 |

Leno Weave |

160±5% |

100,107,113 |

200 |

400 |

5+-0.5 |

5+-0.5 |

|

EG5*5-240 |

240±5% |

300 |

600 |

5+-0.5 |

5+-0.5 |

||

|

EG5*5-260 |

260±5% |

330 |

660 |

5+-0.5 |

5+-0.5 |

||

|

EG5*5-320 |

320±5% |

400 |

800 |

5+-0.5 |

5+-0.5 |

||

|

EG5*5-430 |

430±5% |

600 |

1200 |

5+-0.5 |

5+-0.5 |

||

|

EG6*6-190 |

190±5% |

200 |

400 |

6+-0.5 |

6+-0.5 |

||

|

EG6*6-210 |

210±5% |

200 |

450 |

6+-0.5 |

6+-0.5 |

||

|

EG6*6-240 |

240±5% |

250 |

500 |

6+-0.5 |

6+-0.5 |

||

|

EG6*6-280 |

280±5% |

300 |

600 |

6+-0.5 |

6+-0.5 |

||

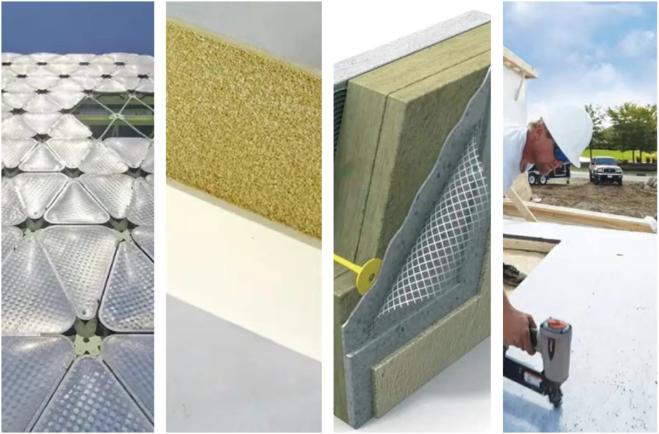

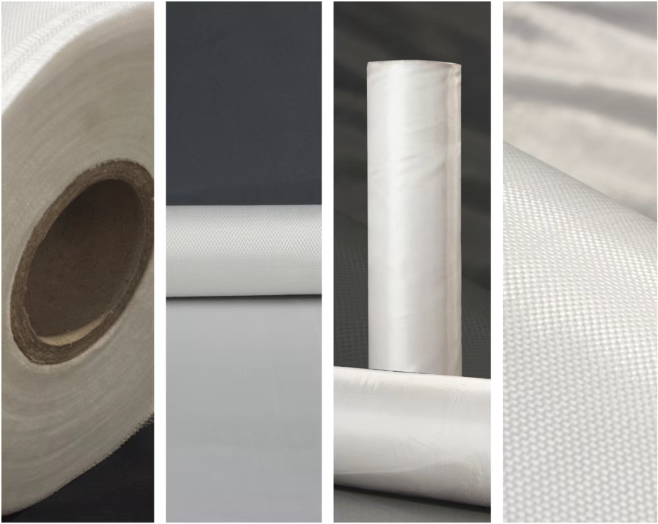

Introduction to Composite Industrial Fabric Products

Fiberglass industrial fabrics primarily include Fiberglass Plain Weave Fabric, Fiberglass Twill Weave Fabric, and Fiberglass Satin Weave Fabric. Plain weave, twill weave, and satin weave fabrics, due to their unique chemical and physical properties, can be compounded with other materials to derive various related materials with extremely wide application range. They are excellent thermal insulation materials, ideal substitutes for asbestos cloth, and feature high tensile strength in both longitudinal and transverse directions, impermeability to gas and water, and good sealing performance. They are mainly used in the preparation of fire-resistant, thermal insulation, and sound insulation materials.

Plain Weave: Features a dense structure, flat and crisp texture, and clear pattern, suitable for most industrial uses such as electrical insulation materials and reinforcing materials. Represented by CW140, CW260, and imitation 7628#.

Twill Weave: Compared to plain weave fabric, the same warp and weft yarns can form a fabric with higher density, greater strength, and a relatively softer and looser structure. It is suitable for general reinforcing materials, fire blankets, air dust removal filter materials, and base cloth for coated products. Represented by 3731# and 3732#.

Satin Weave: Compared to plain and twill weaves, the same warp and weft yarns can weave a fabric with greater density, higher mass per unit area, higher strength, and yet a looser structure with a good hand feel. It is suitable for reinforcing materials with high mechanical performance requirements. Represented by 3784# and 3788#.

The products possess the following performance characteristics:

1.Excellent high- and low-temperature resistance, with a low-temperature limit of -70°C and a high-temperature limit above 280°C;

2.High surface strength; it is both soft and tough, and can be cut and processed;

3.Excellent chemical corrosion resistance, featuring oil resistance, acid resistance, and water resistance;

4.Resistance to heat aging and weather aging, allowing for long-term use in harsh weather conditions while maintaining physical stability;

5.Electrical insulation, possessing a high electrical insulation rating and capable of withstanding high-voltage loads;

Application Fields

1.Aluminum Foil Composite: Fiberglass cloth compounded with aluminum foil possesses high strength and excellent thermal insulation effect;

2.Gumming and Coating: Coating with silicone rubber, resin, PVC, PTFE (Polytetrafluoroethylene), acrylic, etc., can meet various customer demands;

3.Pipe Wrapping: Can be used as internal and external anti-corrosion layers for pipes and storage tanks, featuring excellent anti-corrosion performance, good high-temperature resistance, and high strength;

4.Waterproofing Applications: Used together with asphalt and asphalt-based waterproof membranes for roof waterproofing treatment, crack and joint treatment, etc.;

5.Electrical Insulation: Possessing a high electrical insulation rating, it can withstand high-voltage loads and can be made into insulating cloth, sleeves, etc.;

6.Non-metallic Compensator: As a flexible connection device for pipelines, it can solve the problem of thermal expansion and contraction damage to pipelines, and is now widely used in petroleum, chemical, cement, steel, energy, and other fields, achieving good results.

Product Specifications

|

Model Specification |

Weave |

Width (cm) |

Warp and Weft Density (cm) |

Gram Weight(g/m²) |

Thickness (mm) |

Roll Length (m) |

|

3732 |

Twill Weave |

90-200 |

20*10/18*12 |

430 |

0.40 |

50-400 |

|

3731 |

Twill Weave |

90-200 |

14*10 |

340 |

0.35 |

50-400 |

|

3784 |

Satin Weave |

100-200 |

18*10 |

840 |

0.80 |

50-200 |

|

Imitation 7628 |

Plain Weave |

105,127 |

17*13 |

210 |

0.18 |

50-2000 |

|

CW260 |

Plain Weave |

100-200 |

12*8 |

260 |

0.24 |

50-400 |

|

CW200 |

Plain Weave |

100-200 |

9*8 |

200 |

0.20 |

50-600 |

|

CW140 |

Plain Weave |

100-200 |

12*9 |

140 |

0.12 |

50-800 |

|

CW100 |

Plain Weave |

100-200 |

8*8 |

100 |

0.10 |

50-100 |

Product Introduction

7628# Electronic Fabric is mainly woven from G75# electronic-grade fiberglass yarn (E-GLASS FIBER) using a plain weave structure. It features good electrical insulation performance, fire resistance and flame retardancy, waterproofing, aging resistance, weather resistance, high strength, and high modulus.

Application Fields

Due to its unique physicochemical properties, fiberglass electronic fabric is widely used in the manufacturing of epoxy copper-clad laminates and electrical insulation products, printed circuit boards (PCBs), fireproof boards, insulation boards, as well as in high-demand material sectors such as wind power generation, aviation, and military industries.

Product Specifications

|

Model Specification |

Gram Weight (g/m²) |

Width(mm) |

|

7628-1050 |

210 |

1050 |

|

7628-1140 |

210 |

1140 |

|

7628-1245 |

210 |

1245 |

|

7628-1270 |

210 |

1270 |

Post time: Oct-30-2025