Luxurious interiors, shiny hoods, shocking roars…all show off the arrogance of super sports cars, seemingly far away from ordinary people’s lives, but do you know? In fact, the interiors and hoods of these cars are made of fiberglass products.

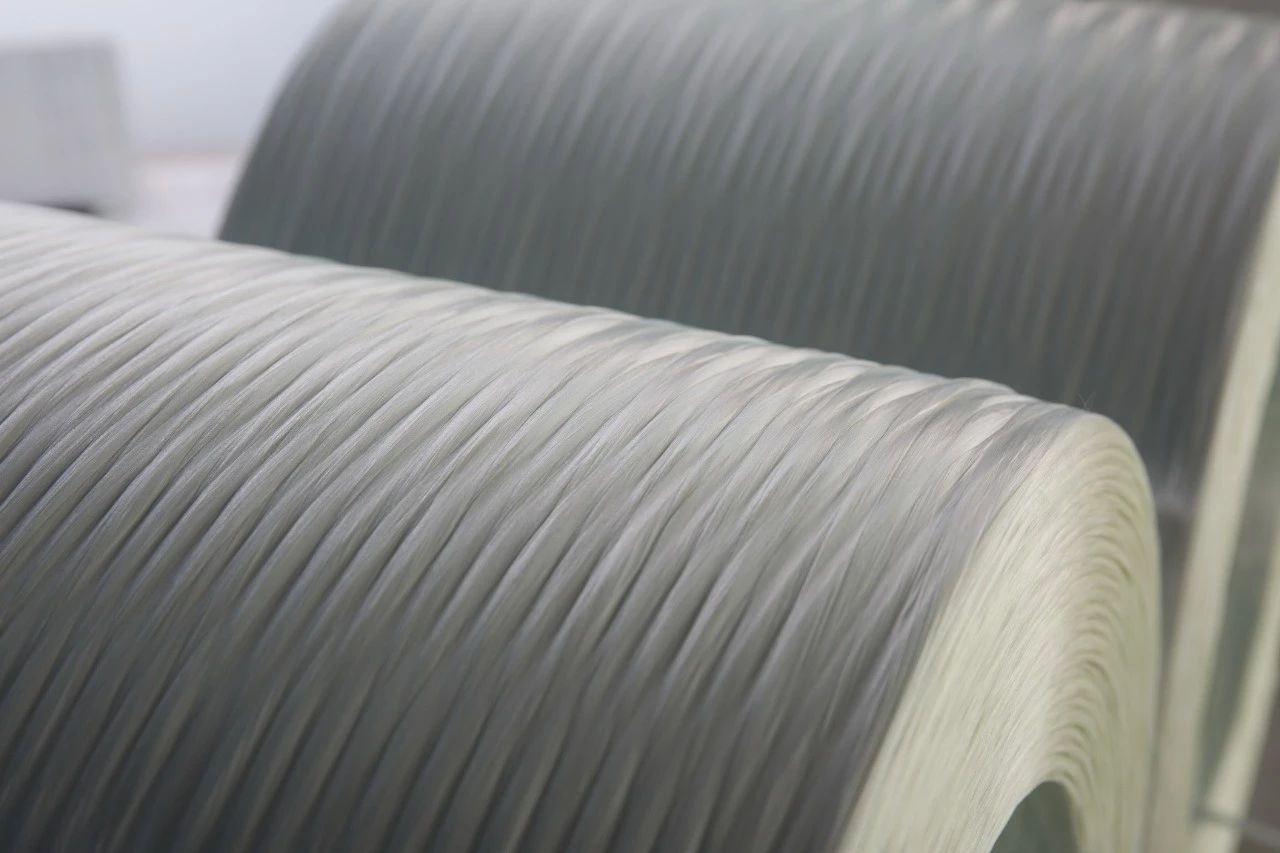

In addition to high-end cars, more ordinary people drive cars and trucks that transport goods, all of which are made of glass fiber. It can be said that the application performance of glass fiber can be extended indefinitely.

At present, glass fiber-reinforced automotive component composite materials can be divided into two types: thermoplastic and thermosetting. The production processes of the two are different, and the uses are also different. Thermosetting glass fiber products for LFT are mainly used for automotive interior parts, such as instrument panel brackets, spare tire boxes, front-end brackets and other non-auto frame components; thermoset SMC fiberglass products are mainly used for automobile hoods, bumpers, and fuel tank separators. Thermal covers and other automotive structural parts.

With the development of the automobile industry and the promotion of energy conservation and environmental protection concepts, lightweight automobiles have become the general trend.The fuel consumption of a car mainly depends on the displacement of the engine and the total mass of the car. On the premise of maintaining the overall quality, performance and cost of the car, reducing the weight of the car can effectively increase the output power and handling, reduce fuel consumption, and reduce exhaust emissions. Studies have shown that for every 10% reduction in vehicle weight, fuel consumption can be reduced by 6-8%. Replacing traditional steel with glass fiber can greatly reduce the weight of the car.

SMC products are an important part of automobile parts. How to reduce the weight of automobiles by improving its performance is an urgent issue for automobile manufacturers to solve.

At present, the most recognized method in the industry is to replace traditional fillers with hollow glass beads, thereby reducing the density of the sheet, to achieve the effect of reducing the weight of the car. But the problem that this brings is that the mechanical properties of the material also decrease. Therefore, in order to ensure mechanical properties under low-density conditions, glass fibers can be used to provide higher mechanical conditions. The SMC products mentioned above are composed of glass fiber, filler and resin.

Glass fiber products for SMC with high strength and surface properties. The product can meet the requirements of mechanical properties and A-level surface properties at the same time, and is suitable for the production of automobile appearance parts and structural parts. Compared with industry competitors under the same conditions, the overall mechanical performance has increased by 20%, which provides a solution to the problem of low-density SMC mechanical performance degradation.

Like those enviable super sports cars, the requirements for power and appearance are much higher than ordinary cars, especially for the appearance and smoothness. SMC uses glass fiber 456 as a new type of glass fiber product for automotive parts, which can meet the customer’s A-level surface, that is, mirror surface requirements, and its brightness is sufficient to match the positioning of supercars.

In addition to SMC products, glass fiber-reinforced thermoplastic materials can also play an important role in the field of replacing steel with plastic in automobiles. High-performance LFT yarn 362H is mainly used in automobile parts such as rearview mirrors, soundproof covers, instrument panel brackets, etc.

LFT technology has high requirements for yarn processability, especially the wear resistance of yarn. The hairiness per kilogram of 362H is very low. Dr. Fan Jiashu of the Product R&D Center confirmed this through experimental comparison. When he set the humidity to 50%, the hairiness per kilogram of 362H is significantly lower than that of the comparison product; when the humidity rises to 75%, the hairiness of all products increases, which is determined by the characteristics of the sizing agent of the yarn itself. But what is amazing is that when the humidity is 75%, the hairiness of 362H is still lower than that of the control group, which shows the excellent abrasion resistance of 362H.

Not only that, the mechanical properties of 362H are also high strength and high toughness.With it, the car will be more resistant to crashes when a severe impact occurs. It will not be as “brittle” as steel, and will not be easily “injured”. This is the same as the surface of 362H. The unique sizing agent treatment is inseparable. The development of high-manufacturability and high-performance LFT-enhanced direct yarn for PP 362H further improves the product system of direct yarn for LFT. Its high dispersion and high lubricity meet the customer’s requirements for processability.

Post time: Jun-17-2021