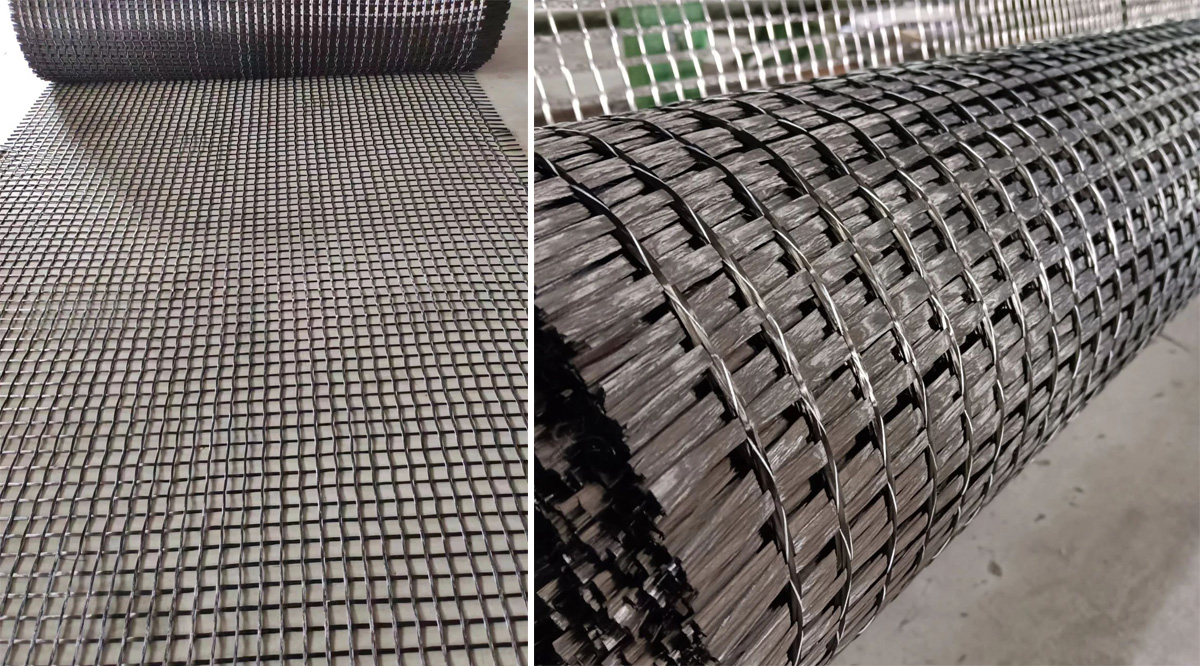

Can you imagine? A “space material” that was once used in rocket casings and wind turbine blades is now rewriting the history of building reinforcement – it’s carbon fiber mesh.

- Aerospace genetics in the 1960s:

The industrial production of carbon fiber filaments allowed this material, which is nine times stronger than steel but three-quarters lighter, to be introduced to mankind for the first time. Initially reserved for “elite sectors” such as aerospace and high-end sports equipment, it was woven using traditional textile techniques, but it had the potential to turn the world upside down.

- The turning point in the “war on steel”:

Conventional reinforcing mesh is like the “old codger” of the construction world: it weighs as much as an elephant (about 25 kg per square meter of reinforcing mesh), and is also afraid of salt, water, and time – - Chloride ion erosion causes the steel reinforcement to expand and crack.

The emergence of carbon fiber mesh cloth completely breaks the deadlock: through directional weaving + epoxy resin impregnation, it makes the thickness of the reinforcing layer from 5cm to 1.5cm, the weight is only 1/4 of the rebar, but also resistant to acid and alkali, seawater, and in the reinforcement of a bridge at the sea, there is no sign of corrosion for 20 years.

Why engineers are rushing to use it? Five hardcore advantages revealed

| Advantages | Traditional steel reinforcement / carbon fiber cloth vs carbon fiber mesh cloth | Life analogy |

| Light as a feather, strong as steel | 15mm thick reinforcement layer can withstand 3400MPa tensile force (equivalent to 1 chopstick to hold up 3 elephants), 75% lighter than the rebar | Like to the building to wear a “bullet-proof undershirt”, but does not increase the weight |

| Construction like painting the wall As simple as | No welding, tying, direct spray polymer mortar, a school reinforcement project in Beijing with it to shorten the construction period by 40% | Save more than tiling, ordinary people can learn |

| Fire resistance to build to outrageous | 400 ℃ high temperature strength remains unchanged, a shopping mall reinforcement through the fire acceptance, while the traditional epoxy resin adhesive will be softened in the 200 ℃ | Equivalent to wearing a “fire suit” to the building “ |

| A hundred years not bad ‘preservative’ | Carbon fiber is an inert material, used in a chemical plant in a strong acidic environment for 15 years without damage, while the rebar has long rusted into slag | than stainless steel is also resistant to manufacturing ”construction vaccine” |

| Two-way anti-seismic “martial arts master” | longitudinal and transverse direction can be tensile, after the earthquake, a school building reinforced with it, and then encountered a level 6 aftershock without new cracks | like to the building equipped with “shock-absorbing springs” |

emphasis: construction must be used to match the polymer mortar! A neighborhood has been mistakenly used ordinary mortar, resulting in the reinforcement layer of drums and fall off — just like the use of glue to stick glass, glue is not the right equal to a waste of work.

From the Forbidden City to the Cross-Sea Bridge: It’s Quietly Changing the World

- The “Invisible Bandage” for Cultural Heritage and Ancient Buildings:

The Beyer Bau, a century-old building at the Technische Universität Dresden in Germany, was in urgent need of reinforcement due to increased loads, but was subject to the restrictions imposed by monument protection. Engineers with 6mm thick carbon fiber mesh cloth + thin layer of mortar, in the bottom of the beam “paste” a layer of “transparent band-aid”, not only so that the load-bearing capacity to enhance 50%, but also did not change the building in the slightest original appearance, and even the Heritage Board experts have praised:”. Like to the old building to do a scarless facelift”.

- Traffic engineering “super patch”:

Florida, the United States, a cross-sea bridge columns, reinforced with carbon fiber mesh cloth in 2003, the strength from the “weak” soared 420%, and now 20 years later, hurricanes are still as stable as a mountain on the coast. Domestic Hong Kong-Zhuhai-Macao Bridge island tunnel project, also quietly used it to do the structural enhancement, against sea water erosion.

- The “age-reversing magic weapon” of the old and dilapidated small:

In an 80′s neighborhood in Beijing, the floor slabs were seriously cracked, and the original plan was to knock down and rebuild. Later with carbon fiber mesh cloth + polymer mortar reinforcement, the cost per square meter is only 200 yuan, than the reconstruction of 80% of the cost of saving, and now the residents say: “feel the house younger 30 years!

The future is here: Self-healing, monitoring “smart materials” are on the way

- A “self-healing doctor” in concrete:

Scientists are developing a carbon fiber mesh that “heals itself” — when microcracks occur in a structure, the mesh can be used as a reinforcement. — When microcracks appear in a structure, capsules in the material rupture to release repair agents that automatically fill the cracks. Tests at a lab in the U.K. have shown that the material could extend the life of concrete by up to 200 years.

- A “health bracelet” for buildings:

embeds fiber-optic sensors in the carbon fiber mesh, like a “smart watch” for buildings: a landmark building in Shanghai uses it to monitor settlement and cracks in real time, and the data is transmitted directly to the management back office, which is 100 times more efficient than the traditional manual inspection. It is 100 times more efficient than traditional manual inspection.

Conscientious advice to engineers and owners

1. Materials choose the right one, twice the result with half the effort: recognize the products with tensile strength ≥ 3400MPa and modulus of elasticity ≥ 230GPa, and you can ask the manufacturers to provide test reports.

2. Don’t be lazy in construction: the base surface must be polished clean, and the polymer mortar should be mixed according to the proportion.

3. Old building renovation priority: compared with demolition and reconstruction, carbon fiber mesh reinforcement can retain the original appearance of the building, but also save more than 60% of the cost.

Conclusion

When the aerospace materials “down to earth” to the construction field, we suddenly found: the original reinforcement can not need to make great efforts, the original old building can also be “reverse growth”. Carbon fiber mesh cloth is like a “superhero” in the construction industry, with light, strong and durable characteristics, so that every old building has the opportunity to renew its life – and this may only be the beginning of the material revolution.

Post time: Jun-26-2025