Hollow glass microspheres and their composite materials

High-strength solid buoyancy materials for deep-sea applications are generally composed of buoyancy-regulating media (hollow microspheres) and high-strength resin composites. Internationally, these materials achieve densities of 0.4–0.6 g/cm³ and compressive strengths of 40–100 MPa, and have been widely used in various deep-sea equipment. Hollow microspheres are special structural materials filled with gas. Based on their material composition, they are mainly divided into organic composite microspheres and inorganic composite microspheres. Research on organic composite microspheres is more active, with reports including polystyrene hollow microspheres and polymethyl methacrylate hollow microspheres. Materials used to prepare inorganic microspheres mainly include glass, ceramics, borates, carbon, and fly ash cenospheres.

Hollow Glass Microspheres: Definition and Classification

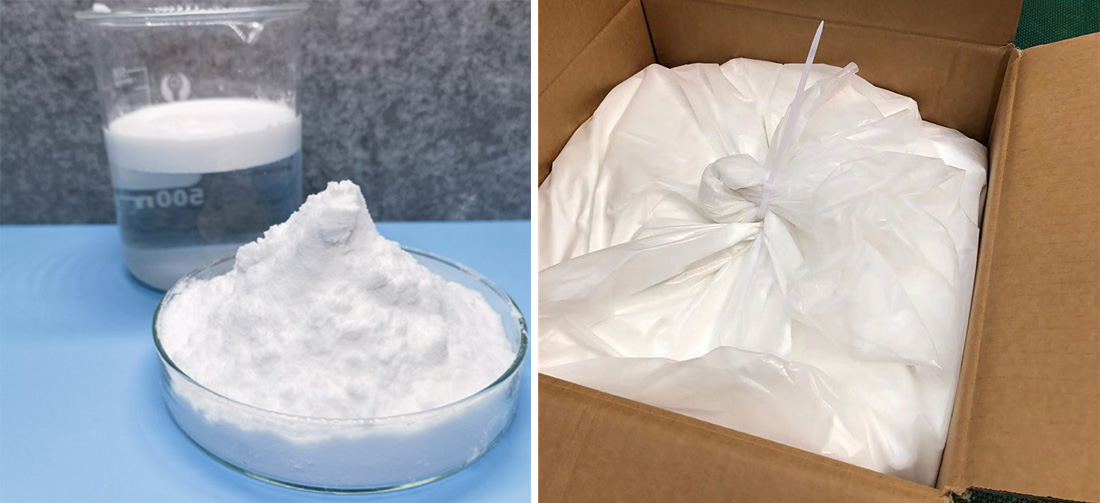

Hollow glass microspheres are a new type of inorganic non-metallic spherical micropowder material with excellent properties such as small particle size, spherical shape, light weight, sound insulation, heat insulation, wear resistance, and high temperature resistance. Hollow glass microspheres have been widely used in aerospace materials, hydrogen storage materials, solid buoyancy materials, thermal insulation materials, building materials, and paints and coatings. They are generally divided into two categories:

① Cenospheres, mainly composed of SiO2 and metal oxides, can be obtained from fly ash produced during power generation in thermal power plants. Although cenospheres are less expensive, they have poor purity, a wide particle size distribution, and in particular, a particle density generally greater than 0.6 g/cm3, making them unsuitable for preparing buoyancy materials for deep-sea applications.

② Artificially synthesized glass microspheres, whose strength, density, and other physicochemical properties can be controlled by adjusting process parameters and raw material formulations. Although more expensive, they have a wider range of applications.

Characteristics of Hollow Glass Microspheres

The widespread application of hollow glass microspheres in solid buoyancy materials is inseparable from their excellent characteristics.

① Hollow glass microspheres have a hollow internal structure, resulting in light weight, low density, and low thermal conductivity. This not only significantly reduces the density of composite materials but also endows them with excellent thermal insulation, sound insulation, electrical insulation, and optical properties.

② Hollow glass microspheres are spherical in shape, possessing the advantages of low porosity (ideal filler) and minimal polymer absorption by the spheres, thus having little impact on the matrix’s flowability and viscosity. These characteristics result in a reasonable stress distribution in the composite material, thereby improving its hardness, stiffness, and dimensional stability.

③ Hollow glass microspheres have high strength. Essentially, hollow glass microspheres are thin-walled, sealed spheres with glass as the main component of the shell, exhibiting high strength. This increases the strength of the composite material while maintaining a low density.

Preparation Methods of Hollow Glass Microspheres

There are three main preparation methods:

① Powder method. The glass matrix is first pulverized, a foaming agent is added, and then these small particles are passed through a high-temperature furnace. When the particles soften or melt, gas is generated within the glass. As the gas expands, the particles become hollow spheres, which are then collected using a cyclone separator or bag filter.

② Droplet method. At a certain temperature, a solution containing a low-melting-point substance is spray-dried or heated in a high-temperature vertical furnace, as in the preparation of highly alkaline microspheres.

③ Dry gel method. This method uses organic alkoxides as raw materials and involves three processes: preparing a dry gel, pulverizing, and foaming at high temperature. All three methods have certain drawbacks: the powder method produces low bead formation rates, the droplet method produces microspheres with poor strength, and the dry gel method has high raw material costs.

Hollow Glass Microsphere Composite Material Substrate and Composite Method

To form a high-strength solid buoyancy material with hollow glass microspheres, the matrix material must possess excellent properties, such as low density, high strength, low viscosity, and good lubricity with the microspheres. Currently used matrix materials include epoxy resin, polyester resin, phenolic resin, and silicone resin. Among these, epoxy resin is the most widely used in actual production due to its high strength, low density, low water absorption, and low curing shrinkage. Glass microspheres can be composited with matrix materials through molding processes such as casting, vacuum impregnation, liquid transfer molding, particle stacking, and compression molding. It is important to emphasize that in order to improve the interfacial condition between the microspheres and the matrix, the surface of the microspheres also needs to be modified, thereby improving the overall performance of the composite material.

Post time: Dec-15-2025