The fourth industrial revolution (Industry 4.0) has changed the way companies in many industries produce and manufacture, and the aviation industry is no exception. Recently, a research project funded by the European Union called MORPHO has also joined the industry 4.0 wave. This project embeds fiber-optic sensors in the blades of aircraft engine intakes to make them cognitively capable during the blade manufacturing process.

Intelligent, multi-functional, multi-material engine blades

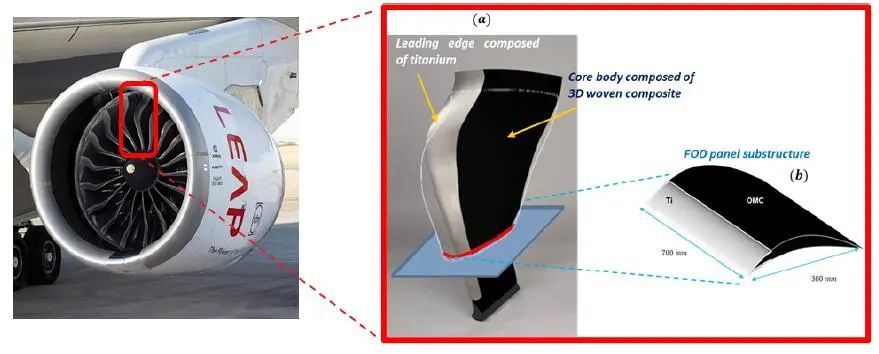

The engine blades are designed and manufactured with a variety of materials, the core matrix is made of three-dimensional braided composite materials, and the leading edge of the blade is made of titanium alloy. This multi-material technology has been successfully used in LEAP® series (1A, 1B, 1C) aero engines, and enables the engine to exhibit high strength and fracture toughness under the condition of increased weight.

Project team members will develop and test core components on the FOD (Foreign Object Damage) panel demonstration. FOD is usually the main reason for the failure of metallic materials under aviation conditions and service environments that tend to be damaged by debris. The MORPHO project uses the FOD panel to represent the chord of the engine blade, that is, the distance from the leading edge to the trailing edge of the blade at a certain height. The main purpose of testing the panel is to verify the design before manufacturing to minimize risk.

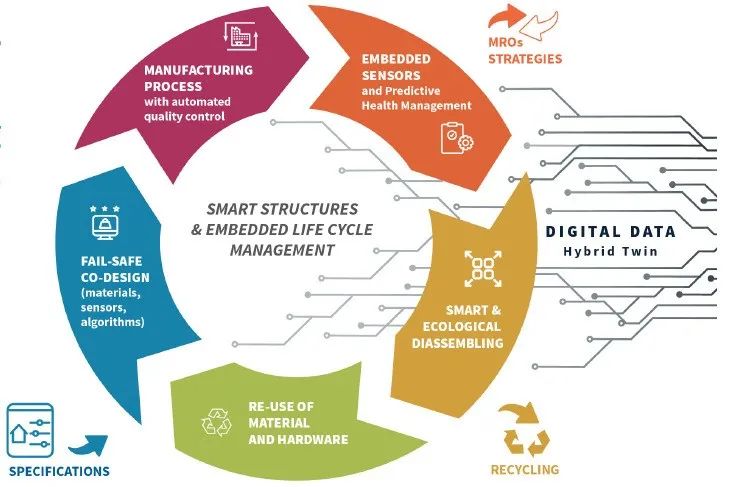

The MORPHO project aims to promote the industrial application of intelligent multi-material aero engine blades (LEAP) through the demonstration of cognitive capabilities in the health monitoring of blade manufacturing processes, services and recycling processes.

The report provides an in-depth analysis of the use of FOD panels. The MORPHO project proposes to embed 3D printed fiber optic sensors in FOD panels, so the blade manufacturing process has cognitive capabilities. Simultaneous development of digital technology and multi-material system models has significantly improved the full life cycle management level of FOD panels, and the development of demonstration parts for analysis and verification runs through the project.

In addition, taking into account the new circular economy action plan issued by the European Union, the MORPHO project will also use laser-induced decomposition and pyrolysis technology to develop environmentally friendly recycling methods for expensive components to ensure that the next generation of intelligent aero-engine blades are efficient, environmentally friendly, maintainable and reliable. Recycling characteristics.

Post time: Sep-28-2021