Product Characteristics

High strength and high efficiency, corrosion resistance, shock resistance, impact resistance, convenient construction, good durability, etc..

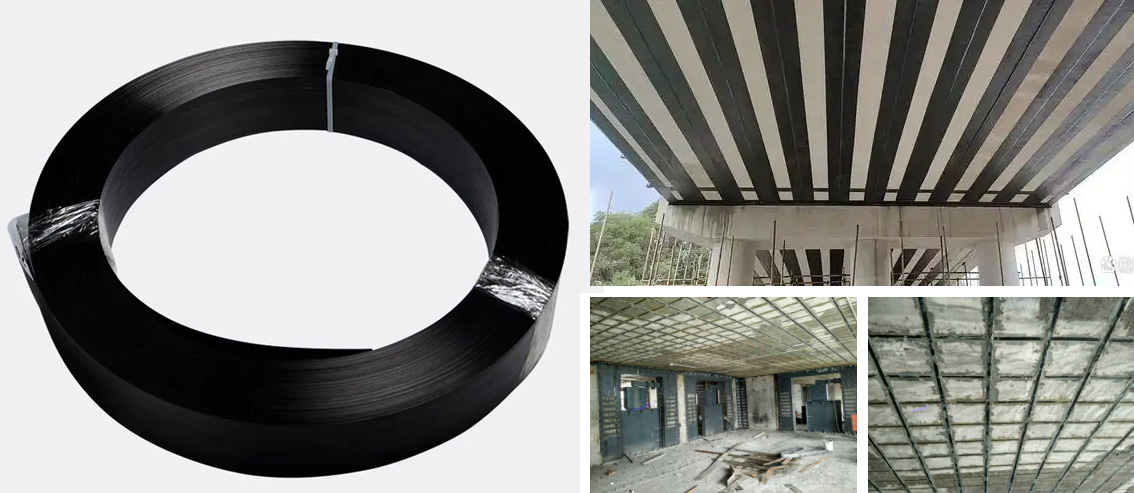

Scope of application

Concrete beam bending, shear reinforcement, concrete floor slabs, bridge deck reinforcement reinforcement, concrete, brick masonry walls, scissor wall reinforcement, tunnels, pools and other reinforcement reinforcement.

Storage and transportation

It should be stored in a dry, cool and ventilated environment, avoiding rain or sun exposure.

Transportation and storage process shall not be subject to extrusion, so as to avoid damage to the carbon fiber.

Construction instructions of Vibranium plate reinforcement

1. Treatment of concrete substrate

(1) Locate and place the line according to the design drawings in the designed paste part.

(2) The concrete surface should be chiseled away from the whitewash layer, oil, dirt, etc., and then use an angle grinder to grind away the 1~2mm thick surface layer and blow clean with a blower to reveal a clean, flat, structurally solid surface, if there are cracks in the reinforced concrete, it should be first depending on the size of the cracks to choose to fill the glue or grouting glue grouting and then reinforcement.

2、Leveling treatment

If there are defects, pits and high waist at the joints of the template on the pasted surface, use leveling adhesive to scrape and fill in the repair to ensure that there is no obvious height difference at the joints, defects and pits are smooth and smooth. Leveling glue curing and then paste carbon fiber board.

3. Paste carbon fiber board

(1) Cut the carbon fiber board according to the size required by the design.

(2) Structural adhesive A component and B component according to the ratio of 2:1 configuration, the use of mixer mixing, mixing time of about 2 ~ 3 minutes, mixing evenly, and to prevent dust impurities mixed. Structural adhesive one-time proportion should not be too much, to ensure that the configuration of the finished within 30 minutes (25 ℃).

(3) The surface of the carbon fiber board should be wiped clean, using plastic scraper will be coated with structural adhesive on the carbon fiber board, structural adhesive thickness of 1-3mm (carbon fiber board center area of 3mm), was the middle of the thick sides of the thin, average thickness of 2mm.

(4) Place the carbon fiber board in the concrete reinforcement base, with a rubber roller uniformly applying enough pressure, so that the structural adhesive from both sides of the overflow, to ensure that there is no hollow, to ensure that the carbon fiber board and the concrete base directly minimum 2mm thickness of adhesive.

(5) Remove the excess adhesive material around the periphery, use the wooden bar or steel frame to support and fix the carbon fiber board, apply pressure appropriately, and remove the support after the structural adhesive is cured. When multiple carbon fiber boards are pasted in parallel, the gap between two boards is not less than 5mm.

(6) paste two layers of carbon fiber board should be continuous paste, the bottom layer of carbon fiber board on both sides should be wiped clean, such as can not be immediately pasted and then open the paste before the bottom layer of carbon fiber board should be re-do cleaning work. If the reinforcement components need to do coating protection, you can brush the protective layer coating after curing resin.

Construction Precautions

1. When the temperature is below 5℃, relative humidity RH>85%, water content of concrete surface is above 4%, and there is the possibility of condensation, the construction shall not be carried out without effective measures. If the construction conditions can not be reached, it is necessary to take the method of local heating of the operating surface to achieve the required relative temperature, humidity and moisture content and other conditions before construction, the construction temperature of 5 ℃ -35 ℃ is appropriate.

2. Because carbon fiber is a good conductor of electricity, it should be kept away from the power supply.

3. Construction resin should be kept away from open fire and direct sunlight, and the unused resin should be sealed.

4. Construction and inspection personnel should wear protective clothing, safety helmets, masks, gloves, protective glasses.

5. when the resin adheres to the skin, should be immediately flushed with soap and water, splash into the eyes with water and timely medical care. 6, each construction is completed, natural conservation within 24 hours to ensure that no external hard impact and other interferences.

7. Each procedure process and after completion, are to take appropriate measures to ensure that no pollution or rainwater intrusion. 8、Configuration of the construction site of the structural adhesive must be kept well ventilated.

9. due to the winding of carbon fiber board has a great tension, in the release of carbon fiber board need 2-3 people with the release of the roll, to prevent the carbon fiber board popping open injury.

10. carbon fiber plate handling process need to be light, forbidden to hard objects and human step on it.

11. Construction encountered a sudden drop in temperature, structural adhesive viscosity will appear large, you can take heating measures, such as tungsten iodine lamps, electric furnaces or water baths and other ways to increase the temperature of the glue before use to preheat to 20 ℃ -40 ℃.

Post time: Apr-27-2025