Light-curing prepreg not only has good construction operability, but also has good corrosion resistance to general acids, alkalis, salts and organic solvents, as well as good mechanical strength after curing, like traditional FRP. These excellent properties make light-curable prepregs suitable for chemical, petroleum storage tanks, above-ground and underground pipelines, etc., to produce anti-corrosion equipment with excellent performance.

1. Application of anti-corrosion lining of oil storage tank

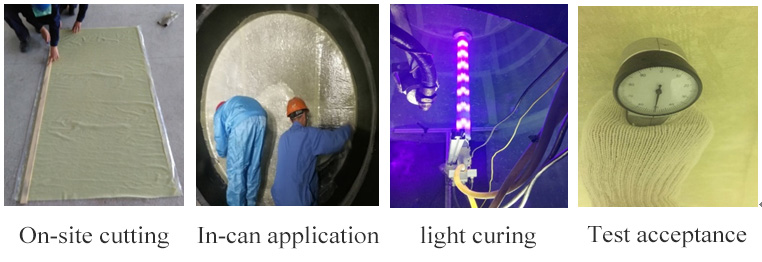

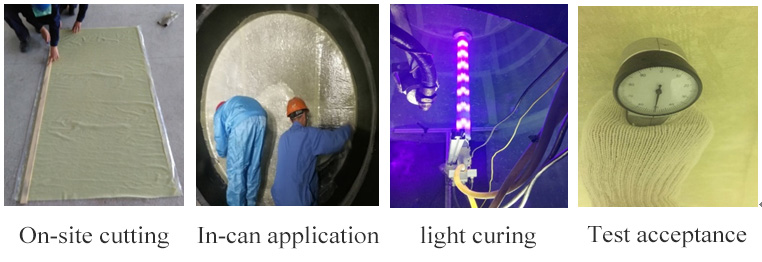

Compared with the repair process of contact molding lining, because the light-curing prepreg can be prefabricated into sheets or rolls, and there are plastic films on the upper and lower surfaces, the solvent volatilization during construction is relatively small, which greatly improves the construction environment and safety. sex. The uncured light-curing prepreg is soft and can be cut or cut according to the needs of the project and then applied directly. It is cured by UV light. The curing time is only 10 to 20 minutes. It is less affected by the environment and can be used all year round. Construction, can be put into use immediately after curing, greatly reducing the construction period and labor costs.

At PetroChina Chongming No. 3 gas station, the light-cured prepreg prepared by MERICAN 9505 was used to renovate the lining of the oil storage tank. The relevant construction conditions are shown in the figure below. The hardness can reach 60, and it has good corrosion resistance.

2. Anti-corrosion application in directional drilling pipeline

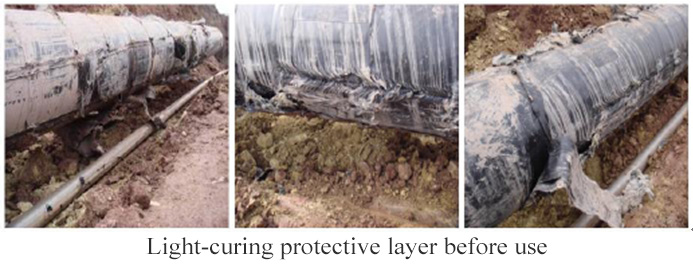

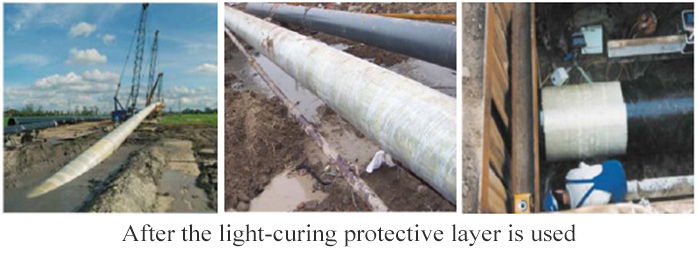

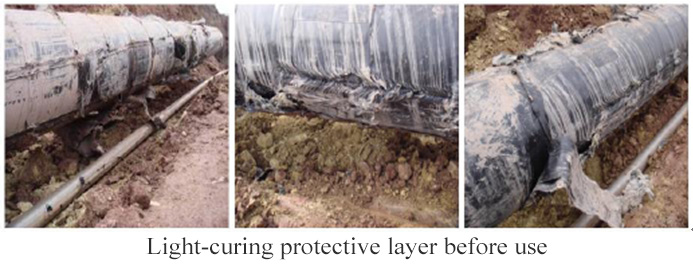

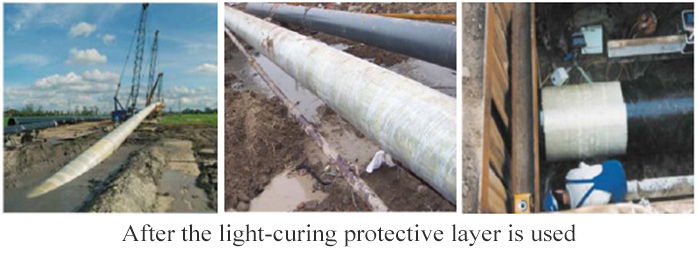

Directional drilling is a pipeline construction process in the engineering technology industry. It is widely used in the construction of oil, natural gas and some municipal pipelines. How to protect the anti-corrosion outer sheath during pipeline directional drilling has always been a difficult problem in the field of pipeline construction. . Most of the flexible pipes are used in the directional drilling crossing, and the hardness of the anti-corrosion layer on the surface of the pipe body is not enough. During the dragging process, the anti-corrosion layer is often cracked or the edge of the patching material is warped or broken, which affects the anti-corrosion effect and seriously endangers the safety of the pipeline. In view of the above problems, the light-cured prepreg can be used as the protective layer of the outer layer of the pipeline. Its main features are high hardness, scratch resistance and friction resistance, which can well protect the anti-corrosion layer.

The comparison of the light-curing protective sleeve before and after the use of the directional drilling pipeline is shown in the following figure:

It can be clearly seen from the comparison that the light-cured prepreg layer has a good protective effect on the pipeline and improves the anti-corrosion performance of the pipeline.

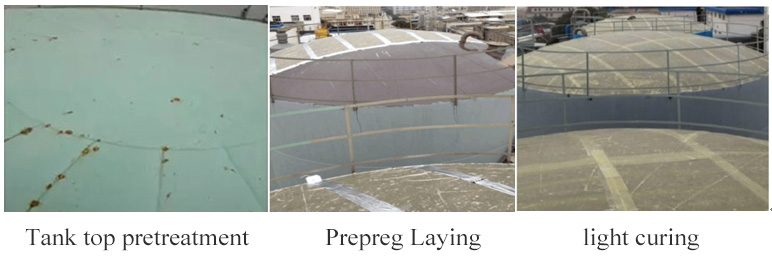

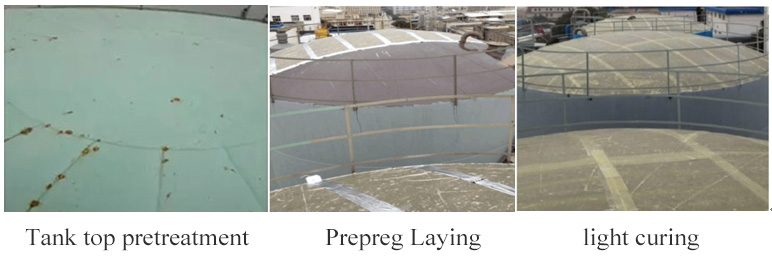

3. Anti-corrosion application of oil and gas storage tank roof

Most of the oil and gas storage tanks are steel metal tanks. Because oil and gas often contain corrosive substances, the corrosion of metal tanks is very serious. For example, under the action of higher temperature in the tank, the harmful gases such as dissolved oxygen, hydrogen sulfide and carbon dioxide will volatilize and cause strong corrosion on the top of the tank, causing serious damage to the top of the tank, which not only causes huge oil and gas loss, but also increases safety. hidden danger. For the safe use of oil and gas storage tanks, local maintenance or replacement of the tank top is required frequently. The traditional method of tank roof repair is to replace the metal tank roof steel plate, which requires the tank to be stopped, cleaned, the construction unit to formulate safety measures, and the safety department to approve layers by layer. The construction period is long and the repair cost is high. However, using light-curing prepreg, the existing tank top is used as a template, and it is designed and cut on site, and it is bonded with the original metal tank top to form a whole. On the basis of maintaining the original tank top strength, The strength of the composite layer is multiplied and can be used as a new solution for the roof repair of oil and gas storage tanks.

In addition to the above-mentioned anti-corrosion fields, light-curing prepregs can also be used in anti-corrosion fields such as pool linings in underground spaces, underground pipes, storage tanks in garbage dumps, ship decks, and power plant renovations. At present, most of the light-curing prepreg sheets on the market are imported products, and the cost is high, which limits their application. However, with the support of the state, the attention of the market, and the increased investment of research and development resources, there will be more and more different types of domestic light-cured prepreg sheets used in different fields.

Post time:

May-25-2022