Adding hollow glass beads to rubber products can bring many advantages:

1、Weight reduction

Rubber products also toward lightweight, durable direction, especially the mature application of microbeads rubber soles, from the conventional density of 1.15g/cm³ or so, add 5-8 parts of the microbeads, reduced to 1.0g/cm³ (commonly known as “floating on the water”), there is a certain degree of R & D capability of customers by adding microbeads will be density of 0.9 or even 0.85g/cm³, significantly reducing the density of rubber, shoes and the same situation before the weight reduction of 20% or so. At present, some customers with certain R & D ability will make the density 0.9 or even 0.85g/cm³ by adding microbeads, which greatly reduces the density of rubber, and the weight of the shoes will be reduced by about 20% under the same situation as before.

2、Heat insulation

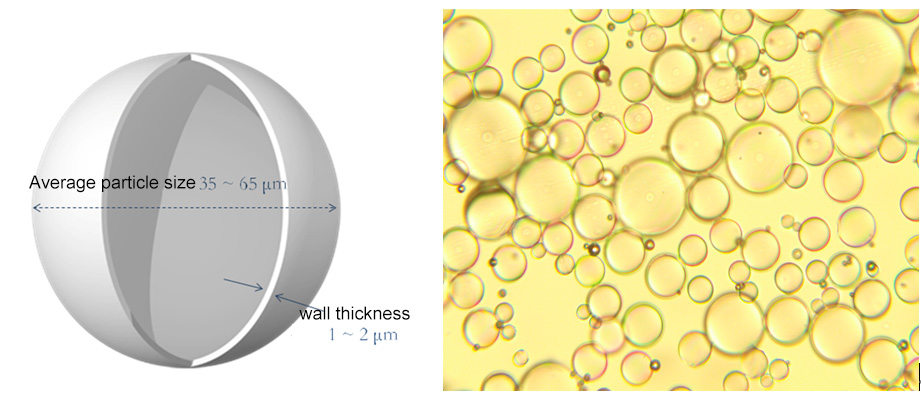

The hollow structure of hollow glass beads gives the beads a low thermal conductivity, as a low thermal conductivity filler added to the rubber material can play a very good thermal insulation effect, such as in the thermal insulation pads, thermal insulation boards and other products used.

3、Sound absorption and noise reduction

Inside the hollow glass beads is thin gas, sound waves in this part will be weakened, in a certain amount of addition to play a very good effect of sound absorption and noise reduction.

4、Good dimensional stability

Beads base material is glass with low coefficient of thermal expansion, good dimensional stability when subjected to thermal shock, added to the rubber material will give the product better dimensional stability.

Suggestions for use in processing:

1, rubber products processing equipment is generally dense refiner, opener, single-screw extruder, etc., because the beads are glass material wall belongs to the rigid particles, in the role of mechanical shear force will be partially broken, the beads will lose its unique functionality after broken.

2, hollow glass beads have different models and corresponding parameters, according to different equipment and product requirements to choose the right beads products is extremely important, St. Leite recommends the use of HL38, HL42, HL50, HS38, HS42 in rubber products.

3, when used in the refining machine, there is a rotor on the rubber material shear, beads can not be avoided by the shear force, so as far as possible to reduce the time of beads in the refining, it is recommended to add in the late refining to ensure that the beads added to the refining 3-5min can be dispersed uniformly; in the refining machine, the roller spacing and the refining time of the crushing of the beads have a greater impact, it is recommended that the roller spacing > 2mm, refining time should not be too long; The overall shear force of single screw extruder is small, relatively speaking, the impact on the microbeads is small, it is recommended to increase the extrusion temperature by 5 ℃, reduce the viscosity of the material is more conducive to extrusion molding, reduce the microbeads broken.

Post time: Jul-21-2023