Facing the increasingly serious problem of environmental pollution, the awareness of social environmental protection has gradually increased, and the trend of using natural materials has also matured. The environmentally friendly, lightweight, low energy consumption and renewable characteristics of plant fibers have attracted much attention. It will be determined in the foreseeable future There will be a high degree of development. However, plant fiber is a heterogeneous material with a complex composition and structure, and its surface contains hydrophilic hydroxyl groups. The affinity with the matrix requires special treatment to improve the properties of the composite. Plant fibers are used for composite materials, but most of them are limited to short fibers and discontinuous fibers. The original excellent properties have not been fully utilized, and they are only used as fillers. If we can introduce weaving technology, it is a good solution. Plant fiber woven preforms can provide more performance options for composite materials, but they are currently used relatively less and are worthy of further research and development. If we can rethink the traditional fiber utilization method, and introduce modern composite technology concepts to improve it, improve the advantages of use and improve the inherent shortcomings, it will be able to give plant fibers new value and applications.

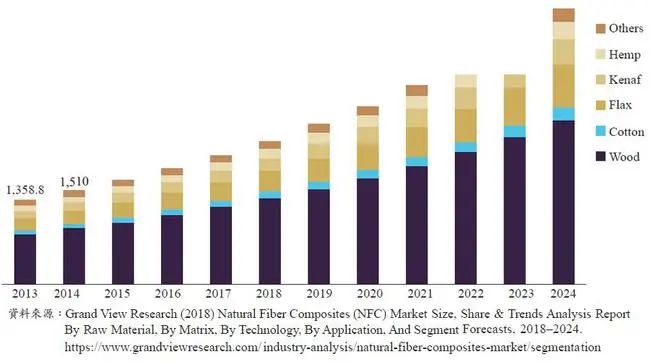

Plant fiber has always been inseparable from human’s daily life. Due to its convenient and renewable characteristics, plant fiber has become an indispensable material for human life.However, with the advancement of technology and the rise of the petrochemical industry, man-made fibers and plastics have gradually replaced plant fibers as mainstream materials due to the advantages of highly developed production technology, product diversification and good durability. However, petroleum is not a renewable resource, and the waste disposal problems caused by the disposal of such products and the large amount of pollution emissions during the manufacturing process have caused people to rethink the usability of materials. Under the trend of environmental protection and sustainability, natural plant fibers have regained attention. In recent years, composite materials that use plant fibers as reinforcement materials have begun to receive attention.

Plant fiber and composite

The composite structure can be designed by the manufacturing process. The matrix-wrapped fiber provides a complete and specific shape of the material, and protects the fiber from deterioration due to environmental influences, and also acts as a bridge to transfer stress between the fibers; while the fiber carries most of the external force with its excellent mechanical properties and can pass The specific arrangement achieves different functions. Due to its low density and high strength, plant fiber can improve mechanical properties and maintain a low density when it is made into FRP composites. In addition, plant fibers are mostly plant cell aggregates, and the cavities and gaps therein can bring excellent heat insulation properties to the material. In the face of external energy (such as vibration), it also benefits from its porosity, which allows the energy to quickly dissipate. Furthermore, the complete production process of plant fiber emits less pollution and uses less chemicals, has a lower operating temperature, has the advantage of lower energy consumption, and the degree of mechanical wear during processing is also lower; in addition, plant fiber is natural Renewable characteristics, sustainable production can be achieved under reasonable management and control. With the assistance of modern technology, the decomposition and weather resistance of materials have been well controlled, so that they can be decomposed after the product’s life cycle, without causing waste accumulation, and the carbon emitted by decomposition is also derived from the initial growth. The carbon source in the atmosphere can be carbon neutral.

Post time: Jun-30-2021