NAWA, which makes nanomaterials, said that a downhill mountain bike team in the United States is using its carbon fiber reinforcement technology to make stronger composite racing wheels.

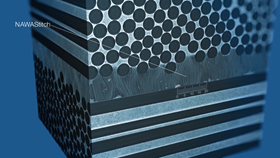

The wheels use the company’s NAWAStitch technology, which consists of a thin film containing trillions of vertically arranged carbon nanotubes (VACNT) arranged perpendicular to the carbon fiber layer of the wheel. As “Nano Velcro”, the tube strengthens the weakest part of the composite: the interface between the layers. These tubes are manufactured by NAWA using a patented process. When applied to composite materials, they can add superior strength to the structure and improve resistance to impact damage. In internal tests, NAWA stated that the shear strength of NAWAStitch-reinforced carbon fiber composites has increased by 100 times, and the impact resistance has increased by 10 times.

Post time: Jul-08-2021