Hot-selling Fiberglass Smc Roving - E-glass Assembled Roving For Chopping – Beihai Fiberglass

Hot-selling Fiberglass Smc Roving - E-glass Assembled Roving For Chopping – Beihai Fiberglass Detail:

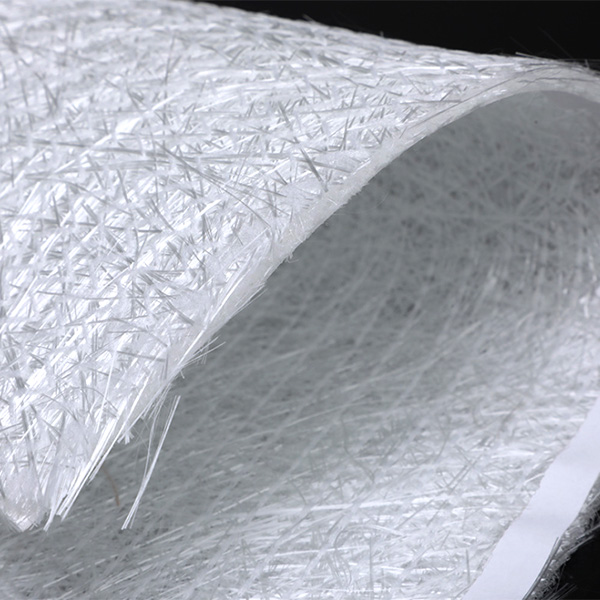

E-glass Assembled Roving For Chopping

Assembled Roving for Chopping is coated with special silane-based sizing, compatible with UP and VE, delivering relatively high resin absorbability and excellent choppability, while its final composite products deliver superior water resistance and excellent chemical corrosion resistance.

Features

●High resin absorbability

●Excellent choppability

●Superior water resistance

● excellent chemical corrosion resistance of final products

Application

It is typically used to manufacture FRP pipes.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHC-01A |

2400, 4800 |

UP, VE |

good dispersion, moderate wet out in resin, good static control |

FRP pipes |

|

BHC-02A |

2400, 4800 |

UP, VE |

few fuzz, good choppability, excellent chemical resistance |

as chop roving for pipe manufacture |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

13 |

| Linear Density, tex |

2400, 4800 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±6 |

≤0.15 |

1.20±0.15 |

125±20 |

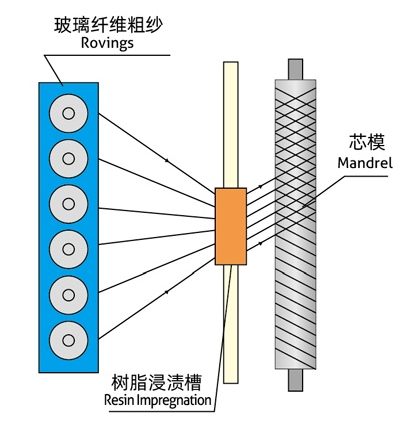

Filament Winding Process

Traditional Filament Winding

In the filament winding process , continuous strands of resin-impregnated glassfiber are wound under tension onto a mandrel in precise geometric patterns tobuild up the part which is then cured to form the finished parts.

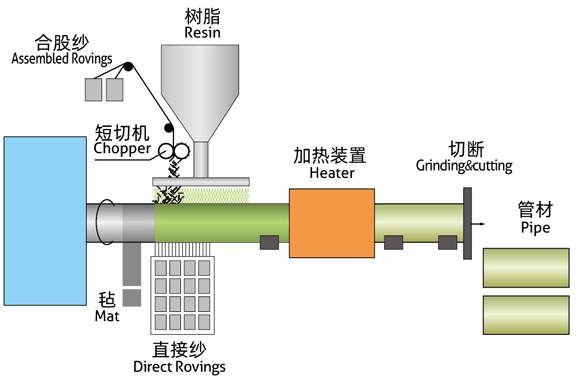

Continuous Filament Winding

Multiple laminate layers , composed of resin , reinforcement glass and other materials are applied to a rotating mandrel , which is formed from a continuous steel band continuously traveling in a cork-screw motion . The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw .

Product detail pictures:

Related Product Guide:

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Hot-selling Fiberglass Smc Roving - E-glass Assembled Roving For Chopping – Beihai Fiberglass , The product will supply to all over the world, such as: Rotterdam, Portugal, Lithuania, The president and all the company members would like to provide qualified goods and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!