High reputation 2400tex Fiberglass Direct Roving - E-glass Assembled Roving For Chopping – Beihai Fiberglass

High reputation 2400tex Fiberglass Direct Roving - E-glass Assembled Roving For Chopping – Beihai Fiberglass Detail:

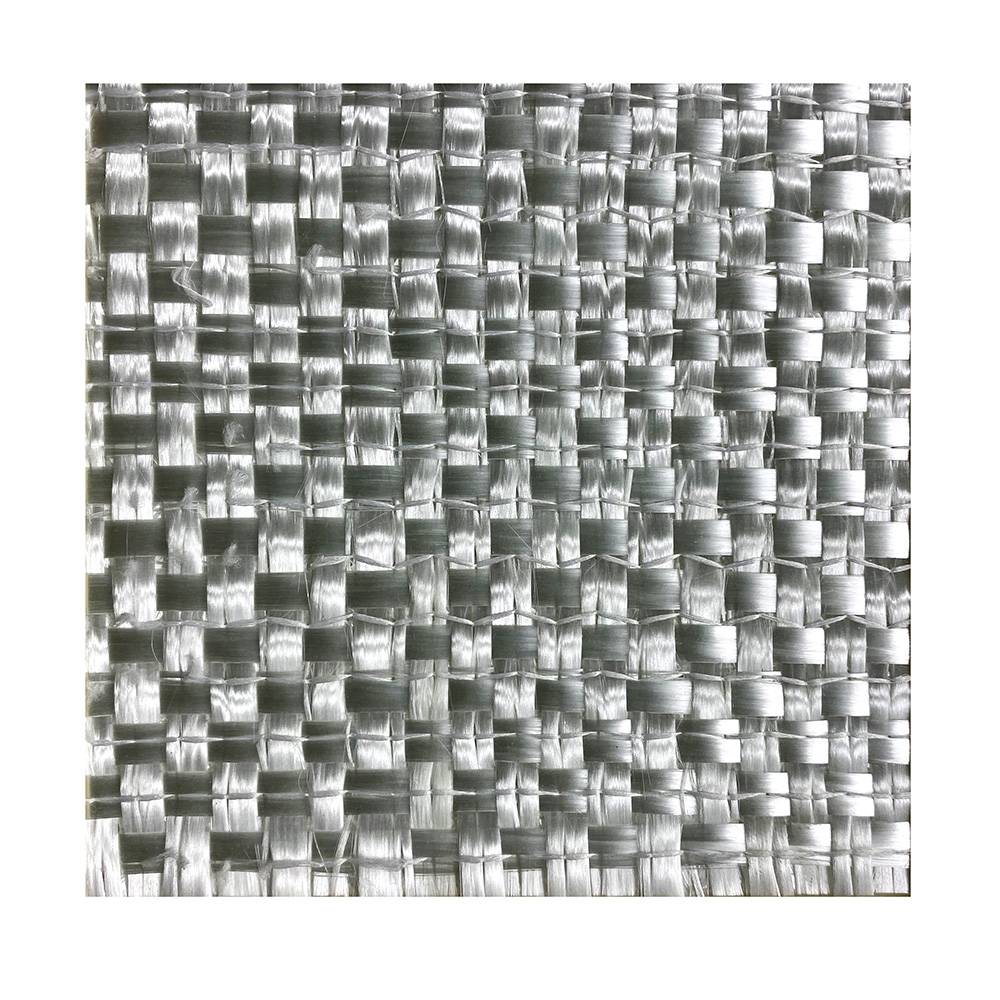

E-glass Assembled Roving For Chopping

Assembled Roving for Chopping is coated with special silane-based sizing, compatible with UP and VE, delivering relatively high resin absorbability and excellent choppability, while its final composite products deliver superior water resistance and excellent chemical corrosion resistance.

Features

●High resin absorbability

●Excellent choppability

●Superior water resistance

● excellent chemical corrosion resistance of final products

Application

It is typically used to manufacture FRP pipes.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHC-01A |

2400, 4800 |

UP, VE |

good dispersion, moderate wet out in resin, good static control |

FRP pipes |

|

BHC-02A |

2400, 4800 |

UP, VE |

few fuzz, good choppability, excellent chemical resistance |

as chop roving for pipe manufacture |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

13 |

| Linear Density, tex |

2400, 4800 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±6 |

≤0.15 |

1.20±0.15 |

125±20 |

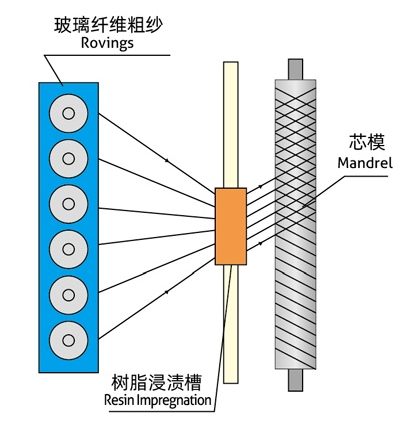

Filament Winding Process

Traditional Filament Winding

In the filament winding process , continuous strands of resin-impregnated glassfiber are wound under tension onto a mandrel in precise geometric patterns tobuild up the part which is then cured to form the finished parts.

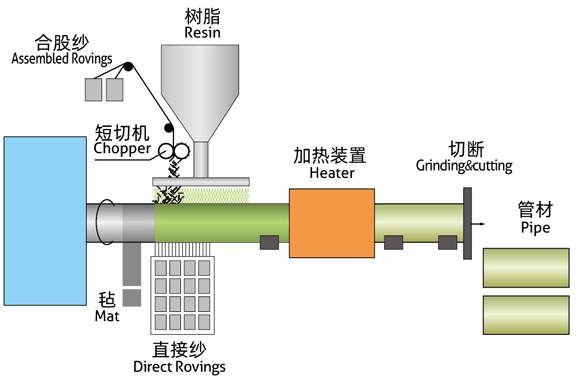

Continuous Filament Winding

Multiple laminate layers , composed of resin , reinforcement glass and other materials are applied to a rotating mandrel , which is formed from a continuous steel band continuously traveling in a cork-screw motion . The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw .

Product detail pictures:

Related Product Guide:

Normally customer-oriented, and it's our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for High reputation 2400tex Fiberglass Direct Roving - E-glass Assembled Roving For Chopping – Beihai Fiberglass , The product will supply to all over the world, such as: Grenada, Costa Rica, Islamabad, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable products quality, increase customers' satisfaction and achieve win-win situation .

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.